Hot time summer in the cellar…

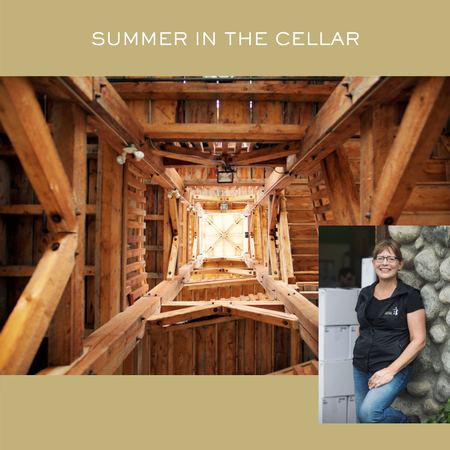

…haha not at Hillside! Our 60-foot tower acts as a ventilation shaft, channeling warm air out of the cellar, while the rock walls built into the Hillside (see what we did there?!) insulate the room. Along with our super-efficient tank cooling jackets this keeps the cellar air temperature generally between 15 and 20 celsius—a great perk on bottling day.

Keeping the tanks cool and full is essential for preserving the flavours and aromas created by the vine until we can get the wine into bottle and to your glass. Once the fruit is picked, un-controlled oxygen attacks and degrades flavour and aroma components, so much of winemaking is designed to protect the juice, then wine from oxygen. We keep tanks and barrels full at all times—this requires a good assortment of tank shapes and sizes as well as a lot of strategizing. Each tank has a stack on top (like a smoke stack), from 3 to 14” in diameter. Wine is filled right into the stack, checked frequently and when possible, we float a small plastic “boat” filled with natural antioxidant on the surface to scavenge oxygen molecules.

Summer hours are also filled with barrel work. Barrels are racked (pumped out, leaving and discarding any sediment), steam-cleaned and refilled. The cellar fills with the aromas of young wine and French oak—another perk. Bordeaux varieties undergo “rack and return” every 3 months, while gamay, pinot noir and syrah are on a 4 to 6 month cycle.

Soon we will begin blending some of the 2019 reds in preparation for pre-harvest bottling. Pinot Noir, Gamay, Syrah and some of the Merlot will be out of barrel and bottled to make room for the 2020 harvest.

I have the best job in the world—where else could a person stand up and walk out of the office right into vineyards?? This is the time to fine-tune yield expectations and finalize pre-harvest ordering of supplies etc. and strategize, strategize, strategize. Most wineries are built to capacity, or soon increase their production to fill capacity, so plans must be in place to make full use of tank/barrel space while realizing the full-potential of the fruit of each block.

Stay tuned for August updates!